...

2025-08-15 20:08

728

↑ « Krebs Pigment & Chemical Company [archive] », DuPont (consulté le ) : « Founded in 1902 by Henrick J. Krebs, Krebs Pigments and Chemical Company produced lithopone, a widely used white paint pigment also manufactured by DuPont. But Krebs' company had another asset of special interest to DuPont. … »

...

2025-08-15 20:04

1424

Assessment of skin penetration and biohazard in vivo

...

2025-08-15 20:03

2708

In the finishing area, the titanium dioxide particles are further processed to improve their properties. This may involve adding other chemicals to modify the particle size, shape, and surface characteristics This may involve adding other chemicals to modify the particle size, shape, and surface characteristics This may involve adding other chemicals to modify the particle size, shape, and surface characteristics This may involve adding other chemicals to modify the particle size, shape, and surface characteristics

This may involve adding other chemicals to modify the particle size, shape, and surface characteristics This may involve adding other chemicals to modify the particle size, shape, and surface characteristics apakah titanium dioxide factory. The finished product is then packaged and shipped to customers around the world.

apakah titanium dioxide factory. The finished product is then packaged and shipped to customers around the world.

...

2025-08-15 19:58

1963

105ºC volatile matter

...

2025-08-15 19:34

1002

...

2025-08-15 19:32

1747

...

2025-08-15 18:57

995

In food, titanium dioxide is often used as an artificial color additive. Tasha Stoiber, senior scientist at the consumer health nonprofit Environmental Working Group, says titanium dioxide can generally be thought of as a paint primer – it often goes on a hard-shelled candy like Skittles before the color is added to give it a uniform shine.

...

2025-08-15 18:11

1706

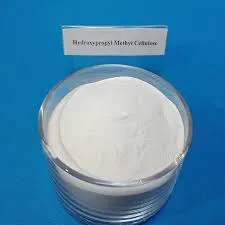

For every industry, we are a single stop company to deliver the chemical powder with standard quality at the right time. Even though we provide a lot of chemical powder, let us discuss the titanium dioxide manufacturer. Our titanium dioxide is highly durable, and it is in the form of white powder, which has its melting point is around 1830 ° C this dioxide is common to all type of the oxide of the metal. The titanium dioxide is not soluble in the water, and it found in the three mineral types, such as tetragonal rutile, rhombic brookite, and anatase.

...

2025-08-15 17:54

689

Other food manufacturers use titanium dioxide to absorb water and keep moisture from clumping or degrading, Paul Westerhoff, PhD, an environmental engineer at Arizona State University who researches the biological and cellular effects of titanium dioxide, told Health.

...

2025-08-15 17:44

1028

↑ « Krebs Pigment & Chemical Company [archive] », DuPont (consulté le ) : « Founded in 1902 by Henrick J. Krebs, Krebs Pigments and Chemical Company produced lithopone, a widely used white paint pigment also manufactured by DuPont. But Krebs' company had another asset of special interest to DuPont. … »

Assessment of skin penetration and biohazard in vivo

In the finishing area, the titanium dioxide particles are further processed to improve their properties. This may involve adding other chemicals to modify the particle size, shape, and surface characteristics This may involve adding other chemicals to modify the particle size, shape, and surface characteristics This may involve adding other chemicals to modify the particle size, shape, and surface characteristics This may involve adding other chemicals to modify the particle size, shape, and surface characteristics

This may involve adding other chemicals to modify the particle size, shape, and surface characteristics This may involve adding other chemicals to modify the particle size, shape, and surface characteristics apakah titanium dioxide factory. The finished product is then packaged and shipped to customers around the world.

apakah titanium dioxide factory. The finished product is then packaged and shipped to customers around the world.

105ºC volatile matter